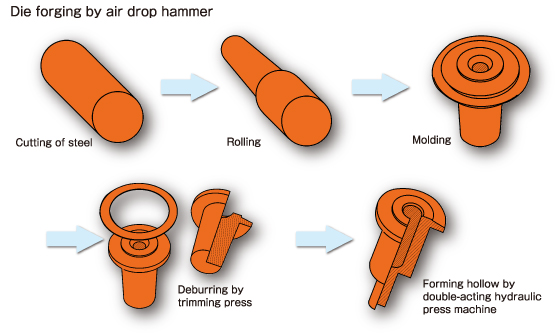

There are important safety components/parts such as thin-walled hollow parts, axle housing of complicated shape, hydraulic cylinders. But, these parts are difficult to make by hot forging.

In our hollow forging line, we make them in a combined forging method using our air drop hammer for stamping and double-acting hydraulic press.

Hollow forging helps to skip machining work to make holes.

It also results in elimination of scrap materials that are otherwise produced during the process of hole making; therefore, it is regarded as eco-friendly.

Thus, our hollow-forged products are highly appreciated by customers.

Reference Products Made by Hollow Equipment